– A research team led by Senior Researcher Sangkyoo Lim has successfully developed biomass-based shape memory polymer fibers capable of simultaneously producing and storing energy. – These artificial muscle fibers, which can lift loads exceeding 56,000 times their own weight, are expected to find applications in industries such as medical robotics, advanced textiles, and wearables industries – The findings of the study were published in the Chemical Engineering Journal

□ A research team led by Senior Researcher Sangkyoo Lim from the Division of Energy & Environmental Technology at the Daegu Gyeongbuk Institute of Science & Technology (DGIST; President Kunwoo Lee) has successfully developed innovative artificial muscle fibers capable of producing and storing energy. The team anticipates that these findings will have broad applications in fields such as advanced textiles, medical robotics, and wearable devices.

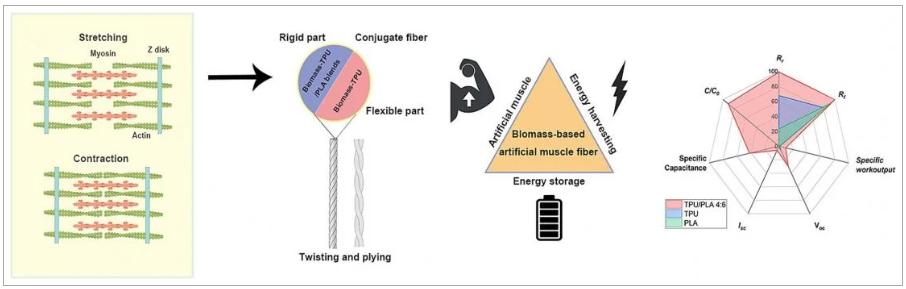

□ The team utilized poly(lactic acid) (PLA), an eco-friendly material derived from crop-based raw materials, and highly durable bio-based thermoplastic polyurethane (TPU) to develop the artificial muscle fibers that mimic the functional and real muscles. Specifically, they enhanced the conventional thermally controlled shape memory function to achieve significantly improved performance. Additionally, the fibers were engineered as multifunctional materials with the added function of producing and storing energy.

□ PLA is an eco-friendly, biodegradable material made from glucose extracted from corn and sugarcane, and it naturally decomposes under specific conditions. TPU, on the other hand, is a highly durable and resilient material that is widely utilized in various products, including industrial sheets, protective films for electronic devices, athletic footwear, and artificial leather.

□ This study meticulously controlled and optimized the ratio of PLA to TPU and engineered the fiber structure to enable mass production. The specialized twisting process enhanced the fibers’ strength, making them 4.18 times stronger than conventional shape memory fibers. Additionally, the fibers demonstrated exceptional durability, retaining over 98% of their resilience even after more than 50 repeated uses. Notably, the fibers exhibited remarkable performance, withstanding loads up to 56,000 times their own weight.

□ In addition to simply memorizing shape, artificial muscle fibers can generate energy from applied pressure. Even after more than 1,000 cycles of repeated charging and discharging, the fibers maintain a stable energy storage capacity, retaining over 90% of their initial performance.

□ Senior Researcher Sangkyoo Lim said, “In this study, we have successfully developed a new artificial muscle fiber technology capable of both producing and storing energy. We anticipate its application across various industries, including robotics, advanced textiles, and wearable devices.”

□ This study was funded by the Industrial Technology International Cooperation Project (International Joint Technology Development Project) under the Ministry of Trade, Industry, and Energy, as well as by the Korea Advanced Institute of Industrial Technology and DGIST’s own project. The findings were published in the Chemical Engineering Journal, a leading international journal in the field of chemical engineering.

Article Credit: asiaresearchnews