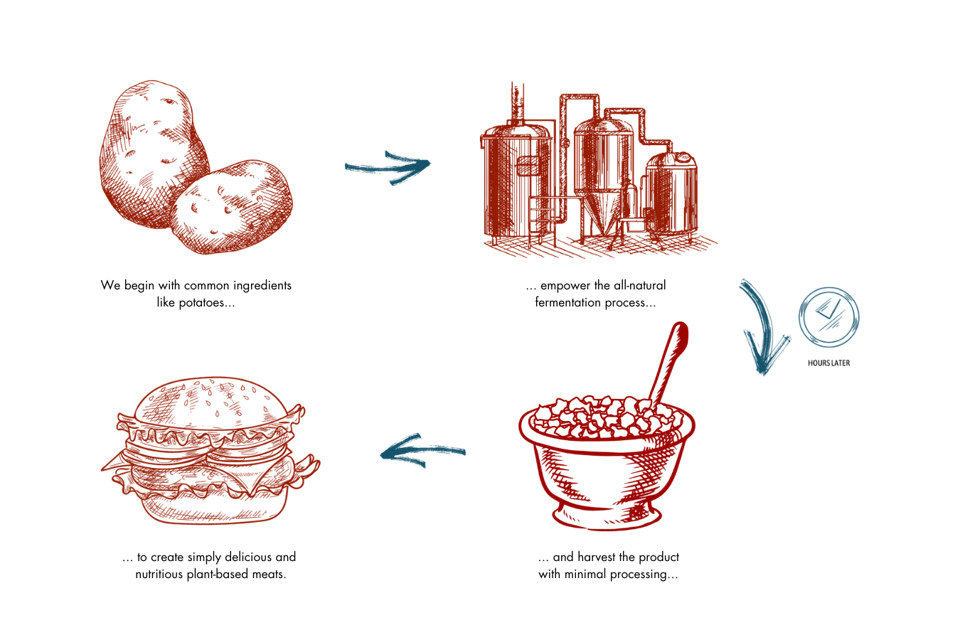

The Better Meat Co. is using a fermentation process to create a realistic plant-based meat alternative that can replicate ground meats or whole muscle cuts: Picture Credit: THE BETTER MEAT CO.

Today’s plant-based food companies are clear on the fact that they’ll need to win over flexitarians to succeed rather than just appealing to the tiny percentage of the population that’s already vegetarian or vegan.

Perhaps no company understands that reality better than The Better Meat Co.

The Sacramento-based B2B company makes plant-based ingredients for companies that turn them into either 100% plant-based meat, seafood and poultry alternatives or blended products that replace a portion of the animal meat with the plant-based alternative.

“We only sell plant-based formulations, both to plant-based companies and also to animal- based companies. Our goal is to help the food industry use fewer animals,” co-founder and CEO Paul Shapiro says.

On Tuesday, the three-year-old company unveiled its newest product, a fermented plant-based ingredient called Rhiza. Rhiza is made by feeding potatoes and sorghum to a specific type of microflora, in a fermentation set-up that resembles a brewery operation, Shapiro explains. The process can create pounds of the plant-based ingredient in several hours, and the end product has a neutral flavor and texture that lends itself to everything from ground meat to whole muscle cuts, he says.

Rhiza is high in protein, iron and fiber, the company says, and the only production limitation is sourcing the quantity of sorghum and potatoes needed to keep fermentation going full-time.

Better Meat Co.’s Plant-Based Roots

The Better Meat Co. built its business on a signature product that is actually made with peas, algae and a few other plant ingredients, and the the products are tailored to the type of meat, poultry or seafood product the customer plans to produce.

The process isn’t unusual in the industry — most plant-based meats are made with protein from either soy, wheat or peas, Shapiro says. The ingredients work, but the process of growing and harvesting the crop, milling it into a powder and isolating it to increase the protein content is time consuming and making it mimic the texture of animal meat has been a big challenge.

Rhiza, the new product unveiled today, provides a way to overcome those challenges and time constraints, Shapiro says.

“We use a microflora and we feed it common ingredients, and [the process] converts those common ingredients into a product that’s naturally textured like meat,” he says. “We create a meat textured product simply through fermentation of common ingredients. You can take it out of the fermenter and add oils and flavors and turn it into a finished product.”

A Man On A Mission

Shapiro has been vegan for 30 years and is the author of the 2018 book “Clean Meat” about the quest to grow meat without animals.

“Basically I was concerned that meat consumption continues to be on the rise,” he says. “Despite a rising awareness of the problems associated with raising animals for food, demand for meat continues to rise. Despite all the progress being made in the plant-based meat sector, we have never raised more animals for food than we do today.”

The book focused on cultured meat, which is made from animal cells. Unlike plant-based alternatives which have become ubiquitous in recent years, cell-based meat is still only approved for sale in Singapore and it’s not clear how long it will be before it’s available in the US or any other global market.

So, the same year the book came out, Shapiro partnered with Joanna Bromley to launch the plant-based food startup, with $1.6 million in pre-seed funding and a mission to meet consumers wherever they are in the journey toward leaving more animals off their plates.

Today, the company has 16 employees including chefs and food scientists, and, after some pandemic-related delays early last year, it raised $8.25 million in a new funding round. The company has also had some version of its signature product on the market since the start and it boasts a list of customers ranging from purely plant-based players to meat companies expanding their offerings of plant-based and blended products.

Each year since it launched, the company has introduced a new and improved version of the original product. But Rhiza, which has been in the works since the beginning, is a whole new type of product.

At its basic level, fermentation is a fairly simple process. But developing and scaling it and getting the end product just right was a time-consuming and complex proposition, made even more so by the pandemic, Shapiro says.

The construction labor needed to build the fermentation plant was constrained, government shutdowns delayed the necessary permits and several times work came to a standstill when one person tested positive and everyone had to quarantine for several weeks.

Now that it’s up and running, the process is less resource intensive than traditional processes for isolating plant-based protein and turning it into meat.

“It’s sustainable and it’s a whole food,” Shapiro says. “We’re optimistic it’s going to help plant-based meat become even more popular in the future because it will help plant-based meat makers make even better products.”

Article Credit: forbes